•

•托盘与未检测到的物体相撞。

例如与丢失的产品相撞

•受外部影响,托盘跨越系统边界旋转。

例如由于单侧重量分布,托盘倾斜过大。

•由于施加的力过大,托盘无法再保持悬浮状态。

示例:由于产品过重由于产品太重

•托盘滞后误差过大。

举例说明如果托盘和定子电机表面之间存在污染,导致托盘制动或阻塞,从而使托盘无法再按照位置设定值运行。

如果托盘发生事故,它会根据其位置变为 "禁用 "或 "未检测到 "状态。在此状态下,穿梭不受控制。

在发生事故的托盘周围会设置一个障碍物,以保持该区域的畅通并防止再次发生碰撞。障碍物的大小取决于托盘的大小、指定的定型和托盘的位置;在 x 和 y 方向上,障碍物距离托盘边缘均为 30 毫米。

如果在系统上手动移动事故托盘,障碍物也会随之移动。障碍物的大小和位置也会相应调整。

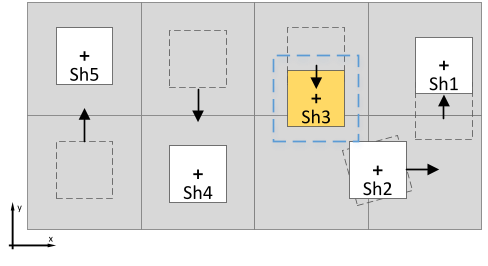

图事故托盘周围的屏障

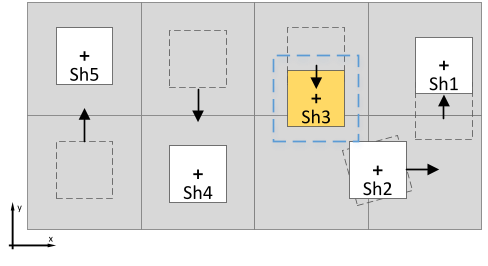

图:事故对其他托盘的影响

如果事故发生时穿梭机(Sh1)位于事故穿梭机(Sh2)附近,并且部分位于所创建的障碍物内,则会立即变为 "障碍物 "状态并停止。当前的移动指令和移动缓冲区中的其他指令将被保留。

未受事故直接影响的托盘(Sh3、Sh4、Sh5)仍可执行移动指令。如果穿梭机(Sh3)在事故附近移动,则会以完整尺寸(包括立体尺寸)停在障碍物前,同时状态也变为 "障碍物"。当前移动指令和移动缓冲区中的其他指令将被保留。

由于事故和障碍物而变为 "障碍物 "状态的托盘(Sh1、Sh3)会在事故解决和障碍物打开后自动恢复其命令。

应用程序中的事故检测

功能块MC_BR_AsmReadInfo_Acp6D用于循环输出事故托盘的数量。如果一辆托盘发生事故,输出上的数字就会增加,并发出带有事故托盘 ID 的日志条目,以便进一步诊断。

功能块MC_BR_AsmGetAccidentSh_Acp6D可用来读出相应的托盘参考信息。

事故后的恢复

事故发生后,用户有几种选择来解决事故情况:

•继续使用事故托盘。

•从系统中移除事故托盘。

o不使用新的托盘。

o更换新的托盘。

为防止再次发生事故,必须从布局中移除外部物体,如丢失的产品。还建议清洁定子电机表面的杂质。

注意!

如果需要对机器进行干预,必须首先将受影响的区域或整个系统恢复到对用户安全的状态。

有关适用的安全规定,请参见用户手册!

继续使用事故托盘

如果事故托盘仍在系统中并处于 "禁用 "状态,则基本上无需对机器进行干预。如果托盘处于 "未检测到 "状态,则由于托盘在 Rz 轴上旋转过远等原因,无法正确检测到托盘。这种情况下需要手动干预,必须将托盘移动到有效位置。

从系统中移除事故托盘

不要使用新的托盘。

在这种情况下,将事故托盘从系统中移除。放置在事故托盘周围的屏障仍然有效。事故托盘的信息和所有指令也将保留。

更换新托盘。

如果事故穿梭机已从系统中移除,则可以在其位置上放置新的穿梭机。屏障会根据新托盘的位置进行动态调整。新托盘将继承事故托盘的信息(包括托盘 ID)和所有命令。对于应用程序而言,这不会造成事故托盘与新托盘之间的差异。

如果使用穿梭机 ID 模式 "AbsoluteID",则只有在下一次启用整个组件时才会分配一个新的 ID。

在上述三种情况下,必须在最后使用功能块MC_BR_ShRecover_Acp6D 解决事故情况。如果事故托盘已从系统中移除,则在调用该功能块时会打开屏障,并丢弃所有来自被移除托盘的命令和信息。事故成功解决后,由于穿梭机已不在系统中,穿梭机引用也会被删除。

如果已损坏的托盘仍在系统中或已被新的托盘取代,则在调用该功能块时会再次检查该托盘。用户可以使用"BufferOption(缓冲区选项) "和"ShortAxesOption(短轴选项)"这两个输入项来选择托盘的定位方式以及运动缓冲区中的命令处理方式。成功执行功能块后,托盘周围的障碍物将被移除。

示例

当所有托盘都执行了移动指令,而事故托盘仍留在系统中时,所示的事故情况将得到解决。

托盘 |

说明 |

Sh1 |

由于处于事故穿梭机的障碍物内,因此在事故期间变为 "障碍物 "状态。当前指令暂停。 当前指令:沿 Y 正方向线性移动 |

Sh2 |

事故托盘变为 "禁用 "状态。当前指令暂停。 当前指令:沿正 x 方向直线运动 |

Sh3 |

起初未受事故影响,但随后由于来到事故穿梭机的障碍物处,状态变为 "障碍物"。当前指令暂停。 当前指令:沿负 y 方向直线运动 |

Sh4 |

不受事故影响。 当前指令:沿负 y 方向线性移动 |

Sh5 |

不受事故影响。 当前指令:沿 y 正方向直线运动 |

使用功能块MC_BR_AsmGetAccidentSh_Acp6D 读出事故托盘的参考值后,使用功能块MC_BR_ShRecover_Acp6D 解决事故情况。输入 "BufferOption "选择值 "mcACP6D_SH_RECOV_BUFFER_PAUSE",输入 "ShortAxesOption "选择值 "mcACP6D_SH_RECOV_SHORTAX_PREV"。

托盘 |

说明 |

Sh1 |

由于事故已解决,状态变为 "Motion(运动)"。恢复当前指令。 当前指令:沿 Y 正方向线性移动 |

Sh2 |

事故托盘受控,移动到初始位置(z、Rx、Ry、Rz)并变为 "空闲 "状态。由于选择了 "mcACP6D_SH_RECOV_BUFFER_PAUSE "选项,当前指令仍处于暂停状态。 当前指令:沿正 x 方向线性移动 |

Sh3 |

由于事故已解决,状态变为 "Motion(运动)"。恢复当前指令。但不久之后,托盘遇到了穿梭机 "Sh2",状态变为 "障碍物"。当前指令再次暂停。 当前指令:向负 y 方向直线运动 |

Sh4 |

托盘没有受到事故影响,继续执行当前指令。 当前指令:沿负 y 方向直线运动 |

Sh5 |

托盘不受事故影响,继续执行当前指令。 当前指令:沿 y 正方向直线运动 |

可使用功能块MC_BR_ShHalt_Acp6D和选项"mcACP6D _ CONTINUE"从应用程序中重新启动已暂停的穿梭机 "Sh2 "的运动。

During operation, situations may arise in which shuttles cannot be controlled predictably.

•

•A shuttle collides with an undetected object.

Example: With a lost product

•The shuttle is rotated across system boundaries by an external influence.

Example: The shuttle tilts too much due to one-sided weight distribution.

•The shuttle can no longer be kept levitating due to too much force being applied.

Example: Due to a too heavy product

•A shuttle has a too high lag error.

Example: If there is contamination between the shuttle and segment surface that brakes or blocks the shuttle, and the shuttle can therefore no longer follow the position setpoint.

Shuttle behavior in the event of accident

If a shuttle has an accident, it changes to state "Disabled" or "Undetected" depending on its position. It is not controlled in this state.

A barrier is placed around the accident shuttle to keep the area clear and prevent further collisions. The size of the barrier depends on the shuttle size, assigned stereotype and shuttle position; it is 30 mm from the shuttle edge in the both the x- and y-directions.

If an accident shuttle is moved manually on the system, the barrier moves along with it. The size and position of the barrier are adjusted accordingly.

Fig.: Barrier around accident shuttles

Fig.: Effects of the accident on other shuttles

If a shuttle (Sh1) is in the vicinity of the accident shuttle (Sh2) at the time of the accident and if it is partly inside the created barrier, it immediately changes to state "Obstacle" and stops. The current movement command and other commands in the movement buffer are retained.

Shuttles (Sh3, Sh4, Sh5) that are not directly affected by the accident can still execute movement commands. If a shuttle (Sh3) moves near the accident, it stops with its full size (including stereotype) in front of the barrier and also changes to state "Obstacle". The current movement command and other commands in the movement buffer are retained.

Shuttles (Sh1, Sh3) that have changed to state "Obstacle" due to the accident and barrier automatically resume their commands as soon as the accident is resolved and the barrier is opened.

Accident detection in the application

Function block MC_BR_AsmReadInfo_Acp6D is used to output the number of accident shuttles cyclically. If a shuttle has an accident, the number on the output increases and a Logger entry with the ID of the accident shuttle is issued for further diagnostics.

Function block MC_BR_AsmGetAccidentSh_Acp6D can be used to read out the corresponding shuttle references.

Recovery after an accident

After an accident, the user has several options to resolve the accident situation:

•Continue to use the accident shuttle.

•Remove the accident shuttle from the system.

oDo not use a new shuttle.

oReplace with a new shuttle.

To prevent further accidents, external objects such as lost products must be removed from the layout. It is also recommended to clean the segment surface from impurities.

Notice!

If it is necessary to intervene in the machine, the affected area or entire system must first be brought to a safe state for the user.

For applicable safety regulations, see the user's manual!

Continuing to use an accident shuttle

If the accident shuttle remains on the system and is in state "Disabled", there is basically no need to intervene in the machine. If the shuttle is in state "Undetected", the shuttle cannot be detected correctly because it has been rotated too far in the Rz axis, for example. Manual intervention is required in this case, and the shuttle must be moved to a valid position.

Removing an accident shuttle from the system

Do not use a new shuttle.

In this case, the accident shuttle removed from the system. The barrier that was placed around the accident shuttle remains in place. The information and all commands of the accident shuttle are also retained.

Replace with a new shuttle.

If the accident shuttle has been removed from the system, a new shuttle can be placed in its position. The barrier dynamically adjusts to the position of the new shuttle. The information, including the shuttle ID, and all commands from the accident shuttle are inherited by the new shuttle. For the application, this results in no difference from the accident shuttle to the new one.

If shuttle ID mode "AbsoluteID" is used, a new ID is only assigned the next time the entire assembly is enabled.

In all three cases, the accident situation must be resolved at the end using function block MC_BR_ShRecover_Acp6D. If the accident shuttle was removed from the system, the barrier is opened and all commands and information from the removed shuttle are discarded when the function block is called. The shuttle reference is also deleted after the accident has been successfully resolved since the shuttle is no longer on the system.

If the shuttle that has been damaged is still on the system or has been replaced by a new shuttle, the shuttle is checked again when the function block is called. The user can use the two inputs "BufferOption" and "ShortAxesOption" to choose how the shuttle should be positioned and what happens to the commands in the movement buffer. The barrier around the shuttle is removed after successful execution of the function block.

Example

The accident situation shown is resolved when all shuttles execute a movement command and the accident shuttle remains on the system.

Shuttle |

Description |

Sh1 |

Changes to state "Obstacle" during the accident since it is inside the barrier of the accident shuttle. The current command is paused. Current command: Linear movement in the positive y-direction |

Sh2 |

The accident shuttle changes to state "Disabled". The current command is paused. Current command: Linear movement in the positive x-direction |

Sh3 |

Not affected by the accident at first but then changes to state "Obstacle" since it comes to the barrier of the accident shuttle. The current command is paused. Current command: Linear movement in the negative y-direction |

Sh4 |

Not affected by the accident. Current command: Linear movement in the negative y-direction |

Sh5 |

Not affected by the accident. Current command: Linear movement in the positive y-direction |

After the reference of the accident shuttle is read out using function block MC_BR_AsmGetAccidentSh_Acp6D, the accident situation is resolved with function block MC_BR_ShRecover_Acp6D. Value "mcACP6D_SH_RECOV_BUFFER_PAUSE" is selected for input "BufferOption", and value "mcACP6D_SH_RECOV_SHORTAX_PREV" is selected for input "ShortAxesOption".

Shuttle |

Description |

Sh1 |

Changes to state "Motion" since the accident has been resolved. The current command is resumed. Current command: Linear movement in the positive y-direction |

Sh2 |

The accident shuttle is controlled, moved to the original position (z, Rx, Ry, Rz) and changes to state "Idle". The current command remains paused due to the selected "mcACP6D_SH_RECOV_BUFFER_PAUSE" option. Current command: Linear movement in the positive x-direction |

Sh3 |

Changes to state "Motion" since the accident has been resolved. The current command is resumed. The shuttle encounters shuttle "Sh2" shortly afterwards, however, and changes to state "Obstacle". The current command is paused again. Current command: Linear movement in the negative y-direction |

Sh4 |

The shuttle is not affected by the accident and continues to execute the current command. Current command: Linear movement in the negative y-direction |

Sh5 |

The shuttle is not affected by the accident and continues to execute the current command. Current command: Linear movement in the positive y-direction |

Function block MC_BR_ShHalt_Acp6D and option "mcACP6D_CONTINUE" can be used to restart the paused movement for shuttle "Sh2" from the application.